Cost to Install Insulated Vinyl Siding A Comprehensive Guide

Cost to install insulated vinyl siding is a critical factor in any home improvement project. Understanding the many elements influencing this cost is essential for making informed decisions. This guide explores the factors affecting pricing, from material costs and labor rates to project scope and customization options.

This detailed analysis delves into the various aspects of insulated vinyl siding installation, offering a comprehensive overview of the cost drivers and practical considerations. It aims to equip homeowners with the knowledge needed to accurately estimate and manage the total project expenses.

Factors Influencing Installation Costs

Insulated vinyl siding offers a durable and energy-efficient exterior upgrade, but the installation cost can vary significantly depending on several factors. Understanding these influences allows homeowners to budget effectively and make informed decisions about their project. Proper assessment of these factors can prevent costly surprises during the installation process.

A comprehensive evaluation of the factors affecting vinyl siding installation costs is crucial for accurate budgeting and informed decision-making. This involves considering the specific characteristics of the project, including materials, labor, and project scope.

Labor Costs

Labor costs represent a substantial portion of the total installation expense. Experienced and skilled installers are essential for a quality job, and their rates vary considerably depending on location, demand, and specific expertise. Factors such as travel time, the number of installers required, and the complexity of the project all impact labor expenses. The need for specialized equipment, such as scaffolding for multi-story homes, also contributes to labor costs.

Material Costs

Material costs are another significant factor. The type of vinyl siding chosen, whether traditional, composite, or fiber cement, directly influences the overall cost. Additional factors include the thickness of the siding, required insulation, and accessories like flashing or trim. Variations in material availability and regional price fluctuations also impact material costs. For example, the price of a rare or imported material will influence the total cost of the project.

Project Complexity

The size and scope of the project directly affect installation costs. A single-story home with a straightforward layout will typically cost less to install than a multi-story home with complex architectural features. The extent of exterior repairs or modifications also influences the project’s overall complexity and cost. The need for specialized work, such as handling challenging rooflines or unique architectural details, will impact the total project cost.

Siding Types and Profiles

Different siding types have varying installation requirements and costs. Traditional vinyl siding is often the most budget-friendly option, while composite or fiber cement siding may command higher prices due to the materials and specialized installation techniques required. The chosen siding profile, whether smooth, textured, or board-and-batten, also affects the installation time and cost. The intricate patterns of certain profiles require more time and precision in installation, thereby increasing costs.

Local Factors

Local labor rates and material availability significantly impact installation costs. Areas with high demand for skilled labor or limited material supply often result in higher installation costs. For instance, coastal regions may have higher material costs due to shipping or availability issues. Similarly, areas with higher construction costs typically see a reflection in siding installation pricing.

Regional Cost Comparison

| Region | Average Installation Cost (per square foot) |

|---|---|

| Northeast | $8-$12 |

| Midwest | $7-$10 |

| South | $6-$9 |

| West | $7-$11 |

Note: These are average estimates and may vary depending on specific project details.

Material Costs: Cost To Install Insulated Vinyl Siding

Vinyl siding installation costs are significantly influenced by the materials used. Understanding the price points for different siding types, supporting materials, and insulation choices is crucial for accurate cost estimations. Factors such as material quality, regional variations, and market fluctuations all play a role in the final price tag.

The cost of vinyl siding materials can vary widely based on several factors, including the type of vinyl, thickness, and any special features. These variations affect not only the cost of the siding itself but also the installation process, as different materials require different installation techniques and potentially more or less supporting materials.

Siding Material Costs per Square Foot

Different types of insulated vinyl siding materials exhibit variations in cost per square foot. These differences are influenced by factors such as the material’s thickness, the manufacturer, and the specific features. A reliable estimate can be obtained by consulting local suppliers and contractors.

| Siding Type | Typical Cost per Square Foot (USD) |

|---|---|

| Standard Insulated Vinyl Siding | $5-$10 |

| Enhanced Insulated Vinyl Siding (e.g., with advanced UV protection) | $8-$15 |

| Premium Insulated Vinyl Siding (e.g., with special textures or finishes) | $12-$20 |

Additional Material Costs

Beyond the siding itself, various supporting materials contribute to the overall installation cost. These include flashing, trim, and fasteners. Proper selection and quality of these materials are essential to ensure the longevity and aesthetic appeal of the finished project.

- Flashing: Protects vulnerable areas from water damage, often made of aluminum or steel, and costs typically range from $2 to $5 per linear foot.

- Trim: Provides a finished look and adds structural support. Costs can vary depending on the type and complexity, from $3 to $8 per linear foot.

- Fasteners: Crucial for securing the siding to the structure. Costs are generally low per fastener, but the quantity needed depends on the size of the project.

Impact of Siding Thickness

Siding thickness directly impacts both material and installation costs. Thicker siding often offers enhanced durability and insulation properties. However, thicker siding generally results in higher material costs and may also require specialized installation techniques, potentially increasing labor costs. For example, a 0.040-inch thick vinyl siding will likely be more expensive than a 0.030-inch thick one.

Insulation Material Costs

Different insulation materials, such as foam and fiberglass, affect the overall project cost. Foam insulation, often in the form of rigid boards, may offer higher insulation values, leading to potentially lower heating and cooling costs. However, this comes with a higher upfront material cost. Fiberglass insulation, a more traditional option, generally costs less per unit but may not offer the same level of performance. The cost difference between the two will vary based on factors such as the type of insulation, the thickness, and the supplier.

Vinyl Siding Price Fluctuations, Cost to install insulated vinyl siding

The price of vinyl siding materials is susceptible to market trends. Economic factors, such as raw material costs and supply chain disruptions, can influence the price. For example, during periods of high demand or material shortages, the cost of vinyl siding can increase. Conversely, periods of oversupply or reduced demand can lead to price reductions. Builders and homeowners should closely monitor market trends and consult local suppliers for up-to-date pricing information.

Labor Costs

Labor costs represent a significant portion of the overall expense for insulated vinyl siding installation. Factors like installer experience, project size, and complexity all play a role in determining the final labor bill. Understanding these factors is crucial for homeowners seeking to accurately budget for this home improvement project.

Labor Cost Breakdown

Labor costs are influenced by several factors, including the experience level of the installers and the complexity of the job. Subcontractors, often less experienced, may have lower hourly rates than licensed and insured installers. Licensed installers, with proven experience and certifications, usually command higher rates, reflecting their expertise and accountability.

Average Hourly Rates for Skilled Labor

The average hourly rate for skilled labor in siding installation varies considerably depending on location and the installer’s experience. In major metropolitan areas, hourly rates tend to be higher than in rural regions. Experienced installers with proven track records and specialized skills might command rates that are 25% or more above the average. Estimating an average hourly rate for siding installers without considering these variables can lead to inaccurate budgeting. For example, a licensed contractor with a strong reputation and a proven history of high-quality work might charge between $50-$75 per hour, whereas a subcontractor might charge between $35-$50.

Impact of Number of Workers on Project Costs

The number of workers needed directly affects the total labor cost. Larger or more complex projects often require more workers to complete the job efficiently and safely. For example, a project covering a significant portion of a house might necessitate two or three installers to manage the work flow and meet deadlines. The project’s scope dictates the number of installers, which in turn directly impacts the total labor cost.

Impact of Installation Complexity on Costs

The complexity of the installation significantly affects labor costs. Challenging rooflines, intricate architectural details, or difficult-to-access areas all increase the time required for installation. For example, a house with a steeply pitched roof or unique architectural features, such as bay windows or dormers, will necessitate more time and specialized skills, leading to higher labor costs.

Permits and Inspections: Time and Costs

Obtaining permits and undergoing necessary inspections are crucial aspects of the installation process. These processes add to the overall project duration. The time spent navigating permit applications and waiting for inspections impacts the project timeline and can inflate the overall labor costs. Permitting and inspection requirements vary by region and local regulations. Delays can impact the project schedule and may lead to additional costs. The cost associated with obtaining permits, plan reviews, and inspections can range from a few hundred dollars to several thousand dollars, depending on local regulations and the complexity of the project.

Average Labor Costs Table

This table provides a general guideline for average labor costs based on project size and complexity. Actual costs may vary depending on location, experience level of installers, and the specifics of the job.

| Project Size/Complexity | Estimated Labor Costs (per square foot) |

|---|---|

| Small (e.g., 500 sq ft) | $5 – $8 |

| Medium (e.g., 1000 sq ft) | $4 – $7 |

| Large (e.g., 2000 sq ft+) | $3 – $6 |

| Complex (e.g., challenging rooflines, many details) | $6 – $10 |

Installation Process & Methods

Insulated vinyl siding installation, while seemingly straightforward, involves specific procedures for optimal results and longevity. Understanding these methods is crucial for homeowners to ensure a proper installation that meets their needs and budget. A well-executed installation protects the house from the elements and increases its overall value.

Different installation methods can significantly impact the final cost and the time required for completion. The choice of method depends on various factors, including the complexity of the project, the specific siding material, and the desired level of insulation. Carefully evaluating the pros and cons of each method is essential to make informed decisions.

Various Installation Methods

Different methods of insulated vinyl siding installation exist, each with its own advantages and disadvantages. These methods cater to different building structures and project requirements. Understanding these approaches allows homeowners to select the most suitable technique for their specific needs.

- Method 1: Direct-to-sheathing installation. This method involves directly fastening the siding to the sheathing of the exterior wall. This method is generally faster and more cost-effective for simpler installations. A key advantage is its relatively straightforward process. However, proper sheathing preparation is critical for long-term structural integrity and to avoid future problems.

- Method 2: Installation over existing siding. In some instances, insulated vinyl siding can be installed over existing siding, provided the existing material is in good condition and stable. This approach may be more cost-effective in cases where replacing the entire existing structure isn’t feasible or financially justifiable. However, this approach might not always be suitable and could be more complex, depending on the existing siding’s condition.

- Method 3: Installation with a furring strip. A furring strip is a thin wooden or metal strip installed on the wall prior to attaching the siding. This method is advantageous for uneven walls or those requiring improved insulation. This approach often provides a more uniform and stable surface for the siding, minimizing potential issues. It is usually a more involved process than direct installation and requires additional material costs.

Installation Process Steps

A systematic approach to installation ensures a professional and high-quality finish. Following a precise sequence of steps is critical for a successful installation.

- Preparation: Thoroughly clean and inspect the exterior wall. Ensure proper ventilation, drainage, and weatherproofing.

- Framing/Furring: Install necessary framing or furring strips as per the chosen method. Properly secure these components for structural integrity. Note that for direct installation, this step may be omitted.

- Installation of Flashing: Carefully install flashing around windows, doors, and other openings to prevent water damage.

- Siding Attachment: Carefully attach the siding panels using appropriate fasteners, ensuring proper alignment and spacing.

- Finishing: Complete the installation by trimming and sealing all joints and edges for a finished look.

Installation Methods Comparison

The following table provides a comparative analysis of different installation methods, considering their cost and timeframe.

| Installation Method | Estimated Cost (USD) | Estimated Time (Days) | Notes |

|---|---|---|---|

| Direct-to-sheathing | $5-10/sq ft | 2-3 | Faster, potentially more cost-effective |

| Over existing siding | $6-12/sq ft | 3-5 | Dependent on existing siding condition |

| Furring strip | $8-15/sq ft | 3-5 | For uneven surfaces or improved insulation |

Impact of Specialized Tools and Equipment

Specialized tools and equipment can significantly impact the installation process and efficiency. Investing in quality tools can lead to quicker installations and potentially reduce labor costs.

Examples include:

Specific siding nailers and fasteners can enhance the installation speed and precision.

Fastener Types and Costs

Different types of fasteners are used for insulated vinyl siding, each with its associated cost.

- Nails: Common nails are suitable for simpler installations. Their cost is typically lower compared to other options. However, their durability may be affected by moisture exposure.

- Screws: Screws offer greater holding power and resilience. Their cost is generally higher than nails, but they ensure better long-term performance.

- Specialty Fasteners: Specialty fasteners designed for insulated vinyl siding are available for specialized applications, often at a higher cost. They are used for better resistance against movement or extreme conditions.

Project Scope and Customization

The cost of insulated vinyl siding installation is significantly influenced by the project’s scope and the desired level of customization. Understanding these factors is crucial for homeowners to accurately estimate the overall project expense. Careful consideration of the project’s size, required customization, and potential prep work is essential for a realistic budget.

Project size and customization options directly affect the total cost of insulated vinyl siding installation. From simple replacements to elaborate renovations, the extent of the work impacts labor hours, material quantities, and potential complexities. Factors like the complexity of the building’s architecture and the number of windows or doors also influence the overall project cost.

Impact of Project Size

The size of the project, measured in square footage, directly correlates with the cost of installation. Larger homes require more materials and labor hours, leading to higher overall expenses. A small, single-story house will have a much lower installation cost than a multi-story home with intricate architectural details. Estimating the precise square footage of the siding area to be replaced is critical for accurate cost calculations. For example, a 2,000 square foot home will require more materials and labor than a 1,000 square foot home.

Customization Options and Their Costs

Customization options, such as choosing specific colors, patterns, or unique architectural features, can significantly affect installation costs. Selecting exotic or uncommon colors might require special ordering and could increase material costs. The complexity of patterns and architectural details, such as bay windows or dormers, can also impact labor costs. These customizations might require specialized installation techniques or extra time, ultimately increasing the total expense. For instance, a house with a complex gable roof will likely have higher labor costs compared to a house with a simple, flat roof.

Replacing Existing Siding and Prep Work

Replacing existing siding often involves additional prep work, such as removing the old siding, repairing or patching the underlying structure, and ensuring proper drainage. This prep work can significantly increase the overall cost of the project. The condition of the existing siding, including signs of damage or decay, directly influences the amount of prep work required and the associated cost. For example, if the old siding is in poor condition, extensive repairs or replacements of damaged parts of the structure might be necessary.

DIY Installation vs. Professional Installation

DIY installation can potentially reduce costs, but it often involves significant risks. DIY projects can result in poor quality work, increased installation time, and potentially hidden problems that require additional repair work, ultimately increasing the overall project cost. Professional installers possess the necessary skills and expertise to ensure proper installation, leading to a higher initial cost but potentially reducing long-term issues and maintenance costs. The quality and longevity of the installation are often worth the extra investment. Furthermore, professional installers handle permits and inspections, potentially saving time and stress for the homeowner.

Project Permitting and Inspection Costs

Obtaining the necessary permits and undergoing building inspections are often required for siding projects, especially in certain regions or municipalities. These costs vary depending on local regulations and the complexity of the project. It’s important to factor these costs into the overall budget. For example, a large commercial project might require more extensive permitting and inspections, leading to higher associated costs.

Summary Table of Costs

| Project Size (sq ft) | Customization Options | Existing Siding Replacement | DIY Installation | Permitting & Inspections | Estimated Total Cost |

|---|---|---|---|---|---|

| 1,000 | Standard Colors | Minor Prep | Lower | Low | $10,000 – $15,000 |

| 2,000 | Custom Colors & Patterns | Moderate Prep | Higher | Medium | $20,000 – $30,000 |

| 3,000 | Unique Architectural Features | Extensive Prep | High | High | $35,000 – $50,000 |

Note: These are estimated ranges and can vary significantly based on local material costs, labor rates, and specific project requirements.

Additional Considerations

Source: trustgemini.com

Beyond the core elements of material and labor costs, several factors can significantly impact the final price and success of your insulated vinyl siding installation. Understanding these additional considerations is crucial for a smooth and cost-effective project.

Beyond the fundamental aspects of material and labor costs, numerous factors can influence the total price and outcome of your insulated vinyl siding installation. Proactive awareness of these additional elements is key to achieving a seamless and cost-effective project.

Impact of Weather Conditions

Weather significantly impacts installation scheduling and costs. Unforeseen inclement weather, such as heavy rain, extreme temperatures, or strong winds, can delay the project. These delays often result in additional labor costs as installers need to adjust their schedules. Furthermore, unfavorable conditions can damage materials, necessitating replacements and increasing the overall project cost. For instance, a sudden, unexpected storm during installation could necessitate significant delays, requiring the siding project to be postponed to a more favorable period, thereby escalating the project’s final cost.

Impact of Warranties and Guarantees

Warranties and guarantees, provided by both the manufacturer of the siding and the contractor, play a critical role in determining the overall cost. Longer warranties often come with a higher upfront price for the materials, reflecting the manufacturer’s confidence in their product. Comprehensive warranties covering potential issues or defects, including labor, extend the protection for the homeowner and can often add to the total cost of the project. A contractor’s warranty on labor is also a critical factor. It assures the homeowner of timely resolution of any issues arising during or after the installation.

Potential Hidden Costs

Hidden costs can easily add to the project’s overall expense. These include, but are not limited to, cleanup costs, disposal fees for old siding, and potential damage to surrounding landscaping or property during the installation process. Proper planning and communication with the contractor about these potential costs are essential to avoid unexpected financial burdens. The contractor should provide a detailed estimate of any extra costs, such as the disposal of old siding or landscaping repair, and these costs should be reflected in the total quote.

Potential Problems During Installation

Various problems can arise during the installation process, potentially impacting the project’s cost. These include issues with the existing structure (e.g., hidden structural problems, improper measurements), challenges with the siding material (e.g., material defects, unsuitable weather conditions), or problems arising from the contractor’s performance (e.g., inadequate preparation, skill deficiency). Thorough site assessments by the contractor and contingency planning for potential issues can minimize the impact of these problems on the project’s cost. For example, if a hidden structural problem is discovered during installation, the project will require additional labor to rectify the issue, increasing the overall cost.

Importance of Multiple Quotes

Obtaining multiple quotes from different contractors is crucial for making an informed decision. Comparing offers allows homeowners to assess the price competitiveness, quality of materials used, and overall service provided. A thorough comparison of quotes, including hidden costs and potential issues, allows for a better understanding of the true project cost.

Choosing a Reliable Contractor

Choosing a reliable and reputable contractor is paramount. Researching their past projects, checking their licenses and insurance, and obtaining references are essential steps. Looking at reviews from past clients, assessing the contractor’s reputation within the community, and verifying their licensing and insurance are crucial. This process can help avoid potential problems and ensure the project is handled professionally. A contractor with a strong track record of successful installations and positive reviews from previous clients is more likely to provide quality work and avoid unexpected problems.

Closing Notes

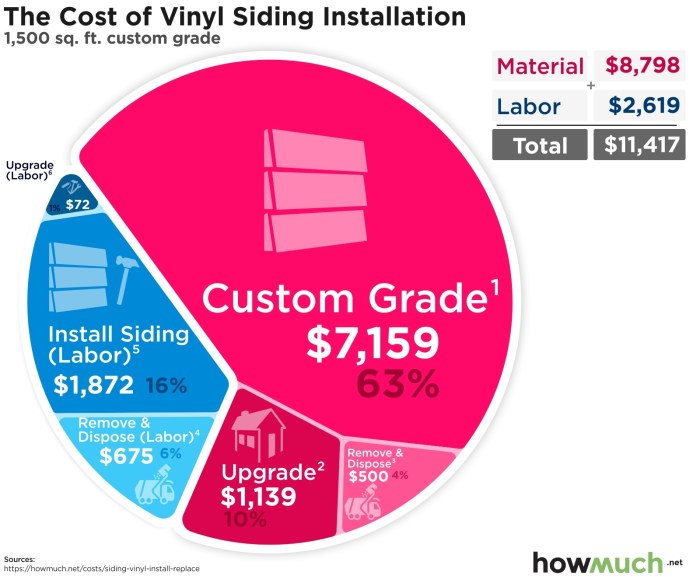

Source: howmuch.net

In conclusion, installing insulated vinyl siding involves a multifaceted process with costs influenced by numerous factors. Careful consideration of material types, labor rates, project size, and customization options is crucial for accurate cost estimations. By understanding the detailed breakdown presented in this guide, homeowners can make well-informed choices and confidently navigate the process of installing this durable and energy-efficient siding.

Ultimately, obtaining multiple quotes from reputable contractors and thoroughly evaluating all aspects of the project, including hidden costs and potential problems, is essential to achieving a successful and cost-effective installation.